AGV guided by magnetic strip

Other solutions

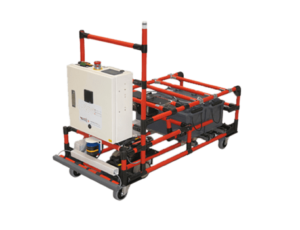

AGV guided by magnetic tape

An automated guided vehicle guided by magnetic tape is an autonomous robot that moves along a predetermined path using various technologies. The AGV follows a magnetic tape stuck on the floor. The spot marker stuck along the magnetic tape gives the instruction to the AGV (turn R/L, stop, speed..)

It is dedicated to the automation and optimization of various flows and is commonly used to transport goods, raw materials, pallets, or any other item for industrial or logistic applications. It interacts and collaborates with workers to lighten repetitive tasks.

The different types of AGV guided by magnetic tape

|

Short Type |

|

Mid-sized Type |

|

Heavy duty type |

|

Eight

|

|

Kit |

Simple & Scalable

Easy Integration

Integration with any ERP/WMS/WCS software.

Robust

Safety

Sensors and depth cameras prevent collision with the operators

Efficient

Eliminate manual operations and improve security.

Aichikikai

Aichikikai Techno system (TCS) is a Japanese company specializing in Automated guided vehicles. Established in 1998, It has sold more than 14 000 AGVs in 30 countries.

Aichikikai provides a large range of robust solutions for every application with reliable technology.

Related Media

Benefits of AGV guided by magnetic tape

Automated Guided Vehicles guided by magnetic tape offer several benefits, including:

Accuracy: AGVs guided by magnetic tape are highly accurate in terms of positioning and guidance. The magnetic tape provides a precise path for the AGV to follow, which ensures that the vehicle stays on track and reaches its destination without any deviation.

Reliability: AGVs guided by magnetic tape are highly reliable, as the magnetic tape provides a clear and consistent path for the vehicle to follow. This ensures that the AGV can operate continuously without any interruptions, reducing downtime and increasing productivity.

Safety: Magnetic tape guidance systems offer an additional layer of safety, as they can be designed to include safety zones or slow-down zones. This ensures that the AGV will slow down or stop when it approaches a hazard or obstacle, reducing the risk of accidents.

Maximum transportable weight: AGVs guided by magnetic tape are capable of transporting heavy loads with ease and efficiency. The magnetic tape provides a precise path for the AGV to follow, which ensures that the vehicle can carry heavy loads without any deviation or loss of control. This makes AGVs guided by magnetic tape an ideal solution for material handling applications that require the transportation of heavy loads over long distances, such as in manufacturing facilities, distribution centers, and warehouses.

Cost-effectiveness: AGVs guided by magnetic tape are often more cost-effective than other types of AGVs, as magnetic tape is a relatively low-cost technology. Additionally, AGVs guided by magnetic tape require less maintenance compared to other types of guidance systems, further reducing the overall cost of ownership.

Isitec International, a key accelerator for the development

Each logistics solution we design is fully adapted to the company requirements. From its design, installation, and commissioning by all collaborators, we take care of each step. For more information about a solution, please contact our teams by phone, or by filling out the contact form.

Reduce your deadlines

Increase your traceability

Feel free to contact us

Download product leaflet