Automated Guided Vehicle (AGV) & Autonomous mobile robots (AMR)

Efficient Industrial Logistics with Isitec’s AGVs and AMRs

AGVs and AMRs are autonomous robots that follow predetermined paths using various technologies. They are primarily used for industrial and logistic applications, transporting goods, raw materials, pallets, and other items. These robots optimize the flow of materials and lighten the workload of human workers by performing repetitive tasks.

There are several types of AGV and AMR robots available, including the AGV shooter, crawling AGV, AGV train, and AGV carrier. Isitec International uses a technology that is simple, efficient, and easily scalable to accommodate changes within your company.

Isitec International’s automated guided vehicle solution is controlled by WCS Isipick®, which not only connects your AGV/AMR to your WMS/ERP system but also to all of your other production and order-picking tools. This provides a comprehensive solution to streamline your workflow and increase efficiency.

Shooter

Simple and effective technology of “karakuri”

The AGV / AMR shooter employs a gravity-based system to automatically load and unload containers like boxes, carton cases, and pallets. Known as “karakuri” in Japanese, this approach is entirely mechanical and delivers the added benefit of reduced automation costs.

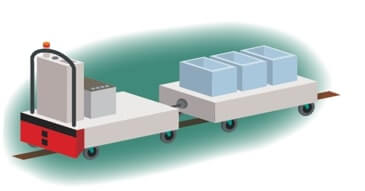

Train

Optimize the movements of your AGV

The AGV train is a prevalent technology in the industry, and it functions as a locomotive to transport one or multiple wagons from station to station. With its LED pointer, the AGV train enables dynamic Pick and Put to light, representing a significant innovation in the field.

Crawling

Ideal for use in confined areas.

The crawling autonomous robot has found widespread use in the automotive industry and large marketplaces. It operates by passing beneath the cart or roller furniture to be carried and then hooking onto it with a “pin hook” system to convey it. The goal of this crawling AGV is to optimize its length with its cart, making it possible to maneuver in tighter spaces.

Carrier

The AGV of industry 4.0

With Industry 4.0, the AGV carrier is set to replace outdated conveyor systems, offering simplified installations that are more scalable. The AGV carrier eliminates the need for rigid infrastructures and allows for LEAN management of your inventory. Say goodbye to fixed installations and embrace the flexibility of AGV carriers.

Partnerhsip with iRAYPLE : the emerging robots in terms of efficiency

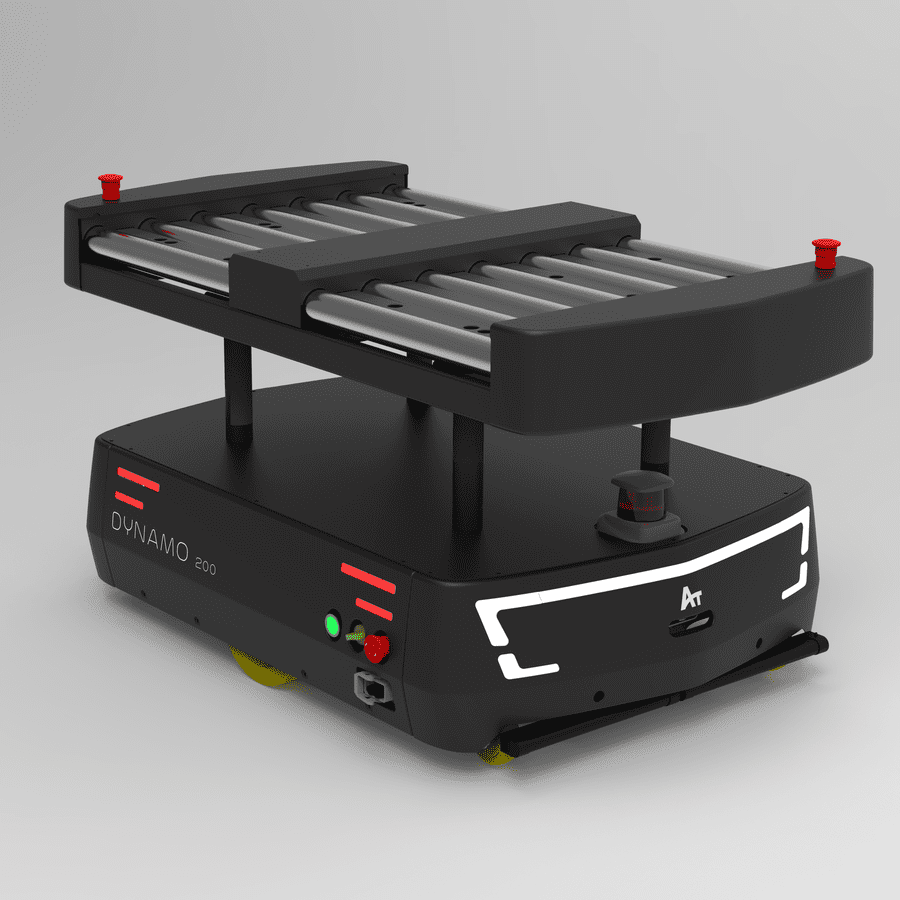

Latent AMR

C060 & C100 :

The 4th generation latent Autonomous Mobile Robot (AMR) stands out with its innovative modular design, featuring an optimized internal structure and enhanced durability. Engineered for ease of use and maintenance, it ensures an exceptional user experience. Equipped with 360° laser protection, it delivers safe and highly reliable human-machine interaction, meeting the demands of modern industrial environments.

Our AGVs & AMRs

Let's find the right solution for you

Automated guided vehicles come with various capacities and technologies. Contact us so we can discuss your needs and put in place the right solution for you.

The Advantages of AGV and AMR Systems

By using AGV and AMR systems, handling efficiency can be improved, and productivity can be increased. Some advantages of these systems include:

24-hour operation

Since they do not require drivers, AGVs and AMRs can work every day and even at night, with battery recharging planned between operations.

Guaranteed safety

AGVs and AMRs follow precise routes, and their movements are monitored to prevent collisions with staff and other obstacles. They also have safety sensors to avoid collisions and can position loads with high accuracy.

Improved working conditions

AGVs and AMRs can handle complex and repetitive tasks for heavier loads, reducing the risk of musculoskeletal disorders for operators.

Lower production costs

With reduced labor costs, efficient and safe transport, and increased recovery rates, AGVs and AMRs can help lower production costs.

Access to inaccessible areas

AGVs and AMRs can operate in areas with extreme temperatures or hazardous materials that are inaccessible to people.